Mechanical tranmission

⚙️ Mechanical Transmission System Description

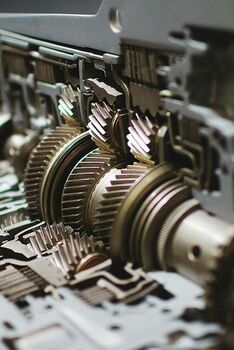

A mechanical transmission system is a crucial component in machinery and equipment that is responsible for transmitting power from a source (like a motor or engine) to a target (such as wheels, shafts, or actuators). It ensures the efficient conversion of torque and speed to match the specific requirements of the machine or application.

🛠️ Key Functions:

- Transfers mechanical energy efficiently

- Adjusts speed, torque, and direction of motion

- Ensures synchronization between input and output components

- Protects equipment from overload using safety mechanisms

🔩 Core Components:

- Gears: Spur, helical, bevel, and worm gears for speed and torque variation

- Shafts & Couplings: Transmit rotational power and align misaligned parts

- Belts & Pulleys / Chains & Sprockets: Flexible power transmission options

- Clutches & Brakes: Control engagement and stoppage of motion

- Bearings & Bushings: Support moving parts and reduce friction

🧰 Types of Mechanical Transmission:

TypeDescriptionGear Drive | High efficiency and precision; ideal for speed and torque control

Belt Drive | Quiet and flexible power transmission with shock absorption

Chain Drive | Suitable for high-load, high-speed applications with minimal slippage

Shaft Drive | Common in automotive and heavy-duty systems for transmitting rotary motion

Belt Drive | Quiet and flexible power transmission with shock absorption

Chain Drive | Suitable for high-load, high-speed applications with minimal slippage

Shaft Drive | Common in automotive and heavy-duty systems for transmitting rotary motion

🏭 Industrial Applications:

- Automotive & heavy vehicles

- Manufacturing machines and CNC systems

- Conveyor and material handling systems

- Agricultural, textile, and packaging machinery

✅ Advantages:

- High mechanical efficiency

- Reliable and long-lasting

- Customizable to operational demands

- Low maintenance with proper lubrication and alignment

Let me know your target audience or product type (e.g., gearbox solutions, conveyor systems), and I can tailor this description even further.